Metal Work Fabrication.

Heavy Equipment Attachments

The process includes: Gas Cutting (CNC), Plasma Cutting (CNC), Laser Cutting, Chamfering, Rolling, Drilling, Molding, Bending, Roll Bending, Machining, Welding, Shot Blasting, Metal Finishing , and Painting

All processes are monitored, controlled and checked by Quality Control Division that assures precision and accuracy of each product.

Our fabrication process is done by certified welder and skilled operator, according to:

1. PPAP Production Part Approved Process and APQP Advanced Product Quality Plan system

2. ISO 9001 Standard Operation Procedure and Work Instruction

3. Production schedule and report

4. Detail engineered drawing

5. Flow chart process

6. Checksheet

QCD Quality, Cost and Delivery are our main concern in measuring our performance.

For more information on our product range, please visit this link http://indonetwork.co.id/Karoseri_Delimajaya/profile/delimajaya-carrosserie-industry-pt-karoseri-delima-jaya.htm

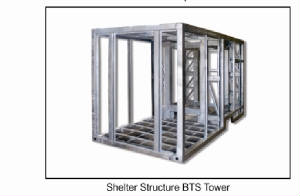

Steel Structure

Engineering Project

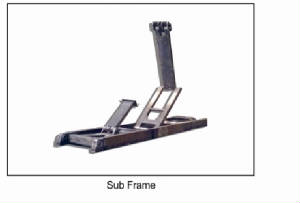

Dump Truck Body Assy: Side Wall, Sub Frame, Tail Gate, Front Wall, Floor

Heavy Equipment Component Parts:

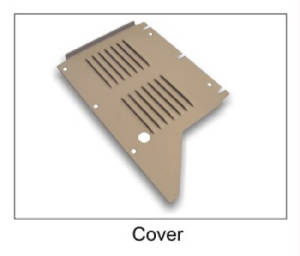

Cover

Under Cover

Tool Box

Hand Rails

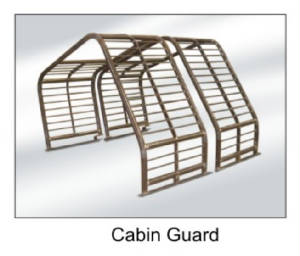

Safety Cabin Guard

Guide Track

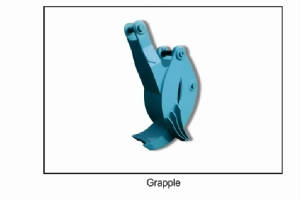

Grapple Excavator

Tail Frame Excavator

Bucket Excavator